Manual inspection fails 20-40% of the time. Human inspectors detect defects at rates between 60-90%, creating massive quality gaps that cost FMCG and automotive manufacturers billions annually. A single recall in food, beverage, or cosmetics ranges from $10 million to $100 million per incident, while automotive recalls triggered by overlooked defects damage brand reputation and consumer trust permanently.

The automotive quality inspection AI system market reached $465.3 million in 2024, driven by manufacturers pursuing zero-defect production standards. AI Defect Detection Solutions address these critical gaps by automating visual inspection processes that once relied entirely on human judgment, delivering 98%+ accuracy at production line speeds that manual methods cannot match.

The Cost of Undetected Defects

Labeling and packaging inconsistencies account for 40% of product rejections in US markets, creating massive rework expenses and distribution delays. FMCG recalls surged 75% in 2021, exposing vulnerabilities in traditional quality control systems that miss subtle defects during high-speed operations. Worker fatigue compounds these problems: inspectors reviewing thousands of items daily inevitably overlook flaws that AI defect detection solutions identify instantly.

Automotive manufacturers face similar challenges. Paint blemishes, surface scratches, dents, and printing errors on chassis identification numbers slip through manual checks, only appearing after vehicles reach customers or dealers. These post-production discoveries trigger expensive warranty claims and erosion of brand value that established manufacturers struggle to rebuild.

60% of FMCG manufacturers integrated AI into quality assurance processes by 2024, achieving 20% reductions in product recalls. The technology delivers ROI through multiple channels: fewer customer complaints, lower rework costs, decreased liability exposure, and preserved brand reputation across competitive markets.

How AI Defect Detection Solutions Transform Manufacturing

Deep learning algorithms trained on millions of defect images distinguish between acceptable variation and true quality failures. Unlike rule-based systems requiring extensive programming for each defect type, modern AI defect detection solutions learn patterns autonomously, adapting to new products without manual reconfiguration.

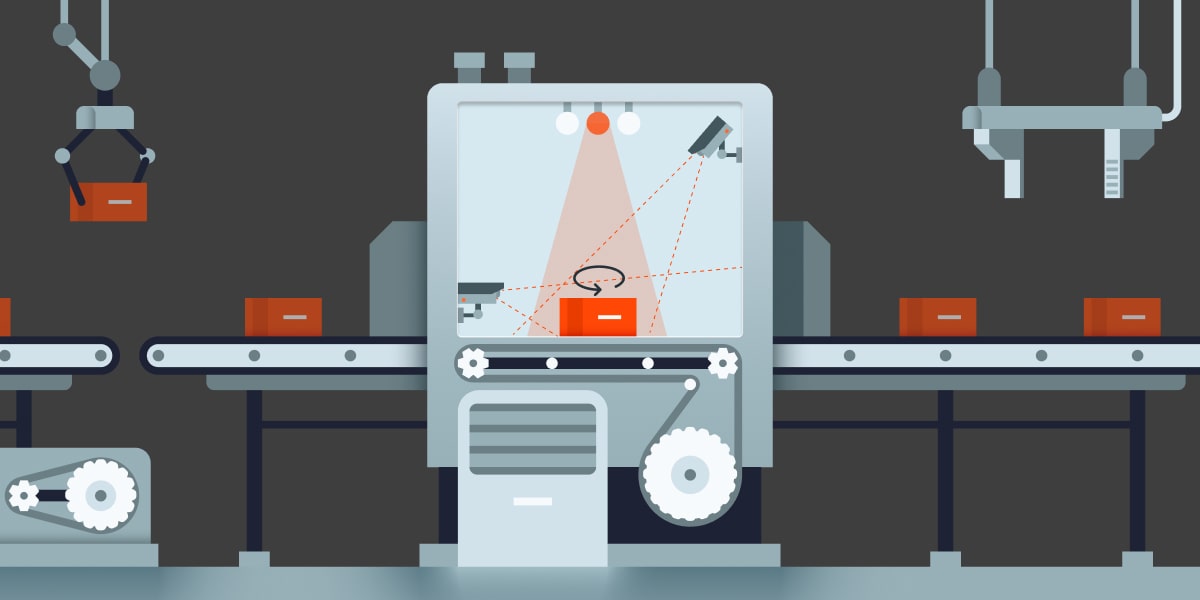

High-resolution cameras capture images at microscopic and macroscopic levels as items move through production lines. Computer vision processes this visual data in milliseconds, identifying surface irregularities, dimensional deviations, assembly errors, and packaging inconsistencies that human eyes miss. The system flags defects instantly, enabling real-time corrections before additional defective units accumulate.

Automotive applications demonstrate this capability across complex inspection scenarios. AI-powered systems detect paint coating irregularities, welding imperfections, component misalignment, and seal integrity failures during assembly. One implementation increased defect detection rates from 75% to over 95%, combining automated inspection with human oversight for optimal results.

FMCG packaging lines benefit similarly. AI defect detection solutions inspect fill levels, cap alignment, label placement, seal integrity, and print quality at speeds exceeding 4,000 inferences per minute. Cookie manufacturers detect subtle film tension changes before they cause visible wrinkles. Beverage producers identify seal inconsistencies that could compromise product safety or shelf life.

Industry-Specific Applications

Automotive manufacturers deploy AI defect detection solutions throughout multi-stage production processes. Initial non-destructive testing verifies raw materials and components entering assembly lines. Inline inspection monitors part placement, orientation, and fastening during build operations. Final checks validate finished vehicle quality before delivery, while predictive systems forecast potential failure points using historical defect patterns.

Electronics manufacturing particularly benefits from nanometer-scale precision. Optical inspection identifies soldering errors, component placement mistakes, and microscopic cracks in circuit boards that affect device reliability. Semiconductor foundries use automated inspection to maintain yield rates, detecting defects in integrated circuits where manual verification proves impossible.

FMCG producers implement AI defect detection solutions across multiple checkpoints. Raw material inspection prevents contaminated or substandard ingredients from entering production. Process monitoring tracks cooking temperatures, mixing consistency, and forming accuracy. Packaging verification ensures correct labeling, proper sealing, and intact containers before products ship.

L’Oréal deployed automated visual inspection across 20 quality checkpoints on assembly lines, reducing defects by 60%. Johnson & Johnson augmented human inspectors with AI systems, improving detection rates from 75% to 95%. These implementations demonstrate how AI defect detection solutions enhance rather than replace skilled workers, providing them with computer-aided vision that never fatigues.

Integration and Implementation

Modern AI defect detection solutions integrate seamlessly with existing manufacturing execution systems, programmable logic controllers, and enterprise resource planning platforms. Edge processing enables instant decisions at inspection points without cloud connectivity delays. Systems communicate directly with robotic rejection mechanisms, automatically diverting defective items while updating production databases in real-time.

The technology requires minimal training data compared to early implementations. Advanced models learn from fewer than 10 acceptable product samples, identifying anomalies without extensive defect libraries. This capability accelerates deployment for new product introductions, allowing manufacturers to implement quality control within days rather than months.

Cost-benefit analysis reveals rapid ROI. Automated inspection eliminates labor expenses for repetitive visual checks while maintaining 24/7 consistency. Reduced scrap rates, lower rework costs, decreased warranty claims, and prevented recalls generate savings exceeding initial system investments within 8-12 months for most applications.

AI-powered image analysis reduced defect detection time by 40% in FMCG packaging operations. Automotive implementations achieved similar efficiency gains while simultaneously improving accuracy and traceability. The combination delivers competitive advantages through superior product quality, faster time-to-market, and enhanced customer satisfaction.

Ready to eliminate defects from your production line? Evaluate AI defect detection solutions designed for your specific manufacturing requirements and quality control challenges.